A powerful work tool

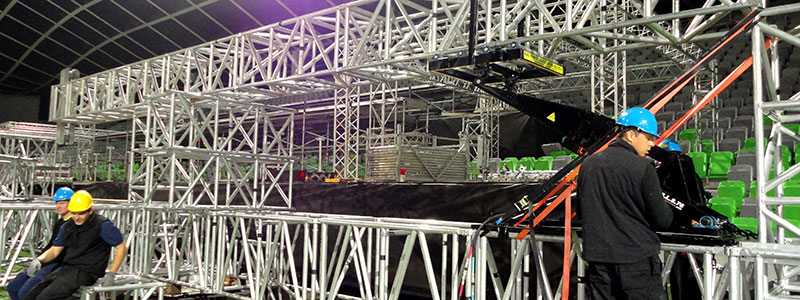

It is perfect for companies who organise and assemble events: concerts, shows, exhibitions, special events, stage covers and so on.

The main advantages of the new GSLS are: maximum safety, total efficiency, great savings and quickness in the assembly of ground support towers.

Maximum savings

As it is transported in a comfortable flight case and as it only needs 2 people to be operated, labour costs are reduced.

Time savings are great, because it only requires 5 minutes to be set up and working.

You will no longer need a large number of people

to raise ground support towers.

Total safety

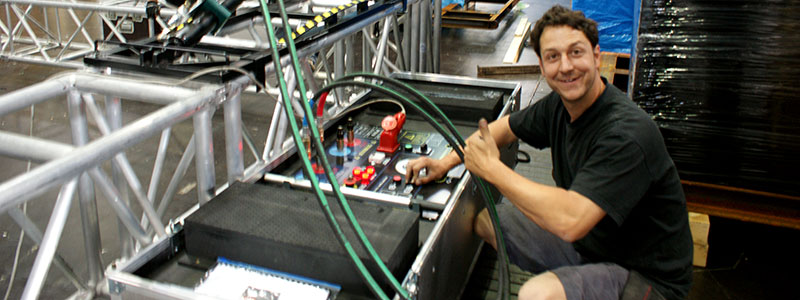

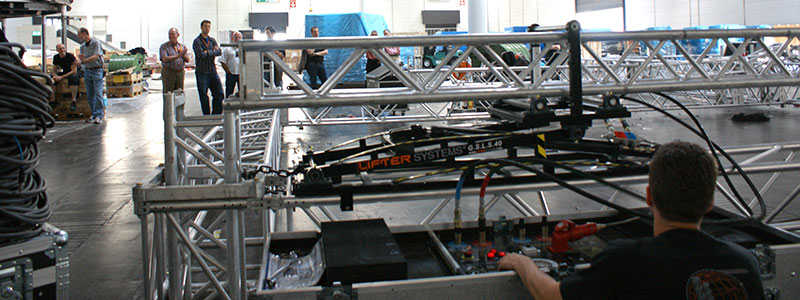

The GSLS does not need people or cranes pushing the tower: everything is done using the control panel located in the flight case.

Your operators will not push the tower manually, so they will avoid occupational hazards.

Unbeatable quickness

Easy to install and easy to use, it reduces assembly time considerably, because it raises a ground support tower in just 5 minutes, chain included.

Additionally, it will improve your workflow, as a larger number of operators will be able to work at other parts of the assembly.

Guaranteed efficiency

Works with all ground support brands: TOMCAT, PROLYTE, LITEC, JAMES THOMAS, MILOS, ATC EUROTRUSS, VMB, FANTEK, FENIX, etc

It is highly efficient, as it has a manual mode to lower towers even without electric current.

And it does not distort or damage aluminium, so it also respects the towers materials, extending their life.

GSLS in 10 steps

- Present the tower in a horizontal position.

- Open the flight case.

- Put the chain around the tower.

- Place the flight case in the right place.

- Tighten the GSLS onto the truss using the clamps.

- Plug on the GSLS.

- Switch on the GSLS using the control panel located in the flight case.

- Place the head of the tower.

- Lift the tower to its vertical position.

- Dismantle the GSLS.